Natural refrigerants from a theoretical point of view

Natural refrigerants from a theoretical point of view

What are natural refrigerants?

Natural refrigerants are substances that exist naturally in the environment. With zero ozone depletion potential (ODP) and very low or zero global warming potential (GWP), they are considered the definitive solution to the environmental damage caused by synthetic refrigerants.

The most widespread natural refrigerants used in HVAC/R applications today are carbon dioxide (CO2, R-744), hydrocarbons such as propane (R-290), isobutane (R-600a) and propylene (R-1270), and ammonia (NH3, R-717). Other natural refrigerants are water (H2O, R-718) and air (R-729), used only for special applications, or sulphur dioxide (SO2) and methyl chloride (CH3Cl), which are no longer used.

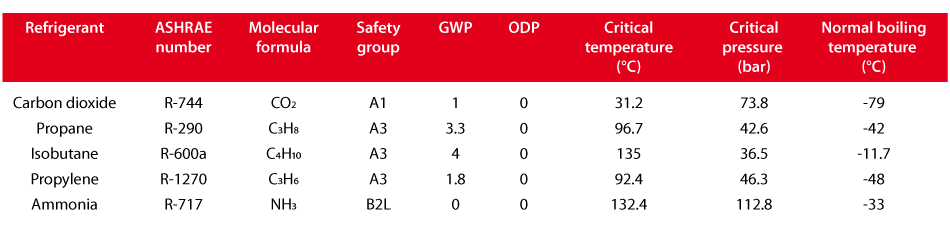

The main characteristics of the most commonly used natural refrigerants are summarised in the following table:

Carbon dioxide

Carbon dioxide (CO2, R-744) is a colourless fluid, heavier than air at normal conditions and odourless at low concentrations. Being a non-flammable and non-toxic substance, it is classified as A1 according to ASHRAE Standard 34.

The effect of R-744 on the ozone layer is null, having an ODP value of 0. As regards its global warming impact, its GWP is 1, which is the reference value for comparing the direct impact of other refrigerants. However, it can be considered that R-744 does not contribute to climate change, as is obtained as a by-product from industrial processes and would otherwise be emitted into the atmosphere.

Other advantages of the use of R-744 as a refrigerant include the fact that is widely available on the market at a very low price. Additionally, R-744 has an excellent coefficient of thermal transfer and extremely low viscosity.

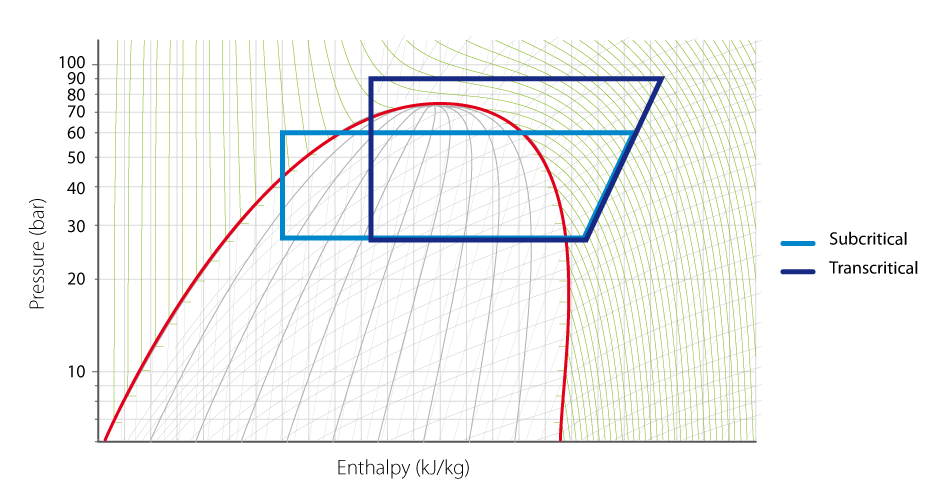

The major challenge of R-744 arises from the fact that the critical point (TC=31.2 °C, PC= 73.8 bars) is easily attainable at a temperature that is common in many climates. This means that the system works in transcritical mode, which means pressure and temperature are no longer related. Measures need to be adopted to keep these values under control, in order to optimise heat exchange and maximise efficiency. Moreover, operating pressures are very high, and this represents the biggest challenge for the components in the installation, such as compressors, valves and piping. Nonetheless, it should be stressed that high pressure means smaller diameter pipes can be used, and pressure drop and compression ratio are lower.

Recently, efforts have been focused on increasing efficiency of R-744 cycles, especially in warm climates. Parallel compressors, ejectors and flooded evaporators are some of the technologies that are now being applied.

As regards the applications in which R-744 is being used as an alternative to synthetic refrigerants, one of the most popular is supermarket refrigeration. Other applications include heat pump water heaters, commercial refrigerated vending machines, secondary expansion systems, industrial and transport refrigeration systems or vehicle air-conditioning systems.

Hydrocarbons

Hydrocarbons are odourless organic compounds made of nothing more than carbon and hydrogen atoms. They are flammable and non-toxic substances, and therefore their safety classification is A3. Its ODP of 0 and extremely low GWP value mean they are harmless to the ozone layer and in terms of global warming. Propane (R-290), isobutane (R-600a) and propylene (R-1270) are the most common hydrocarbons currently used in HVAC/R applications.

Hydrocarbons operate at standard working pressures and have excellent thermodynamic properties, leading to high energy efficiency. For instance, the latent heat of vaporisation of hydrocarbons is almost two times higher than that of the most common HFC refrigerants (R-134a, R-404A and R-507): this means a higher cooling/heating effect for the same refrigerant mass flow.

The major challenge of the use of hydrocarbons as refrigerants comes from their high flammability. This requires a cautious design of the system and compliance with specific requirements for flammable refrigerants defined by standards.

Hydrocarbons are technically viable for small and medium-sized refrigeration and air-conditioning applications, as well as chillers. Applications include domestic fridges, beverage coolers, vending machines, industrial refrigeration, transport refrigeration, small air conditioning systems, chillers, heat pumps and water heaters.

Ammonia

Ammonia (NH3, R-717) is an alkaline and colourless chemical compound at atmospheric pressure. Being a mildly flammable and toxic substance, it is classified as B2L. R-717 is also corrosive, but its strong odour makes it easy to detect. Regarding environmental impact, it does not have any harmful effect on the ozone layer and global warming when released into the atmosphere, thus its ODP and GWP values are 0.

R-717 is widely available on the market at a very low price. Working at standard operating pressures, its good thermodynamic properties, such as high latent heat of vaporisation, puts it among the refrigerants with highest energy efficiency for both medium and low temperature operation.

However, the toxicity and flammability of R-717 has limited its used in public places. Many advances have been made recently to minimise risks for human health, such as the development of hermetically sealed equipment or leak detection systems.

R-717 has mainly been used in industrial refrigeration for many years, however its use is being extended to other applications, such as commercial refrigeration as a secondary fluid.