Standard Configurations

15 years of CO2 experience

STANDARD CONFIGURATIONS

CAREL’s decade of experience in energy savings and CO2 systems is fully expressed in its line of refrigeration controllers. CAREL’s standard CO2 configurations have made the use of CO2 the new reference standard in retail.

CAREL’s decade of experience in energy savings and CO2 systems is fully expressed in its line of refrigeration controllers. CAREL’s standard CO2 configurations have made the use of CO2 the new reference standard in retail.

- Use of natural refrigerant (CO2)

- Standard and consolidated configuration

- Reduced energy consumption

- Control stability and excellent food preservation

- Easy installation and commissioning ensured by a fully totally integrated system

pRack Solutions for CO2

|

pRack solutions for CO2CAREL’s solutions for compressor racks are suitable for both subcritical systems (pRack 300) and transcritical systems (pRack 300T).

|

|||||||

pRack solutions for CO2CAREL’s solutions for compressor racks are suitable for both subcritical systems (pRack 300) and transcritical systems (pRack 300T). |

||||||

|

||||||

|

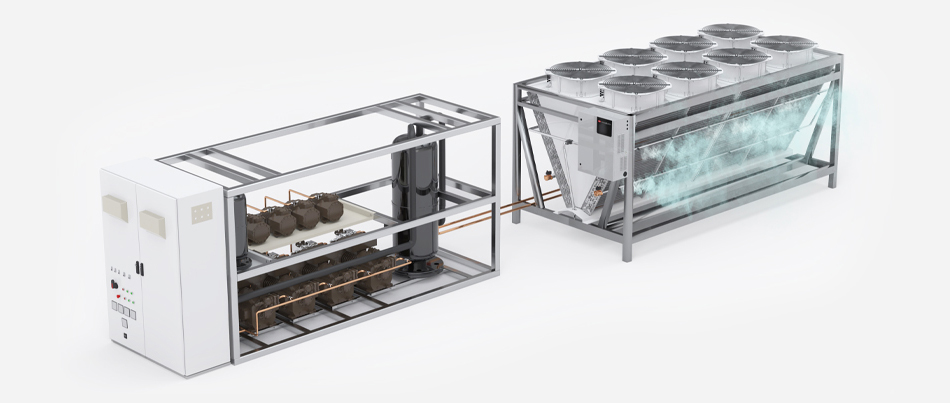

Transcritical booster pack

Transcritical booster pack

|

|

The use of an additional suction line, called intermediate or parallel, improves energy efficiency and makes this type of system particularly suitable for milder climates.

read more |

|

|

Cascade vs Pumped

Cascade CO2 |

Pumped CO2 |

|

|

|

|

| read more | |

|

Cascade CO2

|

|

|

Pumped CO2

|

|

| read more |

CO2 Compressor racks components

CO2 Compressor racks components

|

|

||

|

Expansion board (for pRack 300T)

|

R744 electronic expansion valves

|

chillBooster for evaporative cooling

|

|

|

||

|

|

||

|

|

||

|

|

||

|

chillBooster for evaporative cooling

|

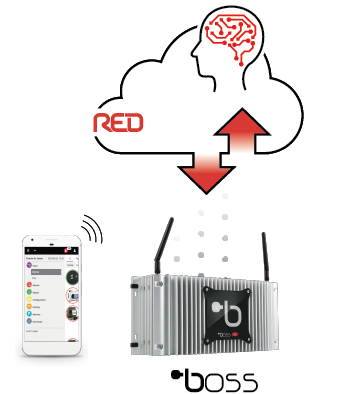

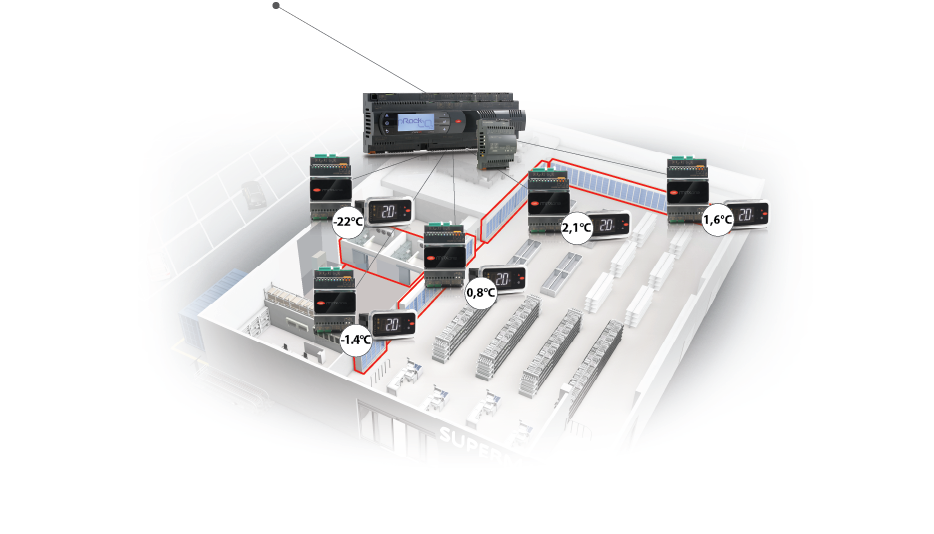

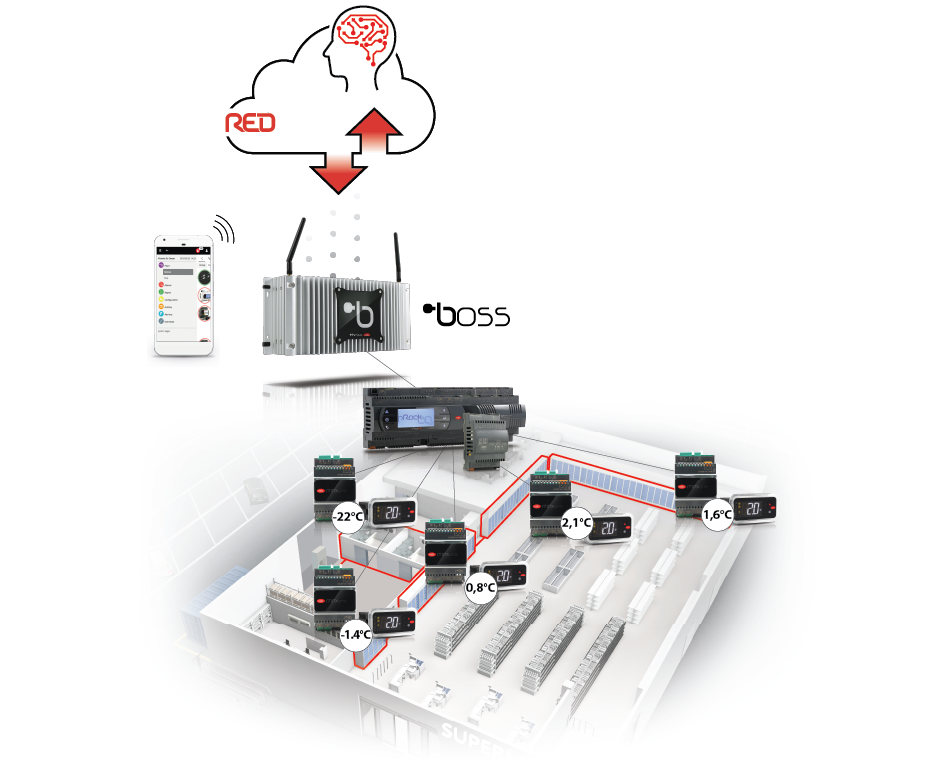

Standard Configurations connectivity

A centralised and integrated system

|

|

The integrated solution comprising the pRack controller and the boss supervisor ensures:

|