CONTINUOUS MODULATION for transcritical CO2 systems

CONTINUOUS MODULATION

for transcritical CO2 systems

Continuous modulation represents the cutting edge of CAREL’s solutions. Through this, maximum efficiency can always be achieved in all operating conditions, and now also in transcritical CO2 booster systems.

Continuous modulation represents the cutting edge of CAREL’s solutions. Through this, maximum efficiency can always be achieved in all operating conditions, and now also in transcritical CO2 booster systems.

- Natural refrigerant (CO2)

- Ideal for small and medium formats

- High energy efficiency and perfect food preservation thanks to the widest range of modulation on the market

- Compact, light and low-noise unit

- Total connectivity

pR Multi DC booster pack CO2

|

pR multi DC booster pack CO2The CO2 booster system with CAREL DC modulating compressors is the integrated solution that brings energy savings and environmental benefits through the use of CO2 with continuous modulation, for small and medium store formats.

|

||||||

| Download the brochure | |||||||

pR Multi DC booster pack CO2The CO2 booster system with Carel DC modulating compressors is the integrated solution that brings energy savings and environmental benefits through the use of CO2 with continuous modulation, for small and medium store formats. |

||||||

|

||||||

|

||||||

| Download the brochure |

MultiDC Envelope

|

|

|

|

|

|

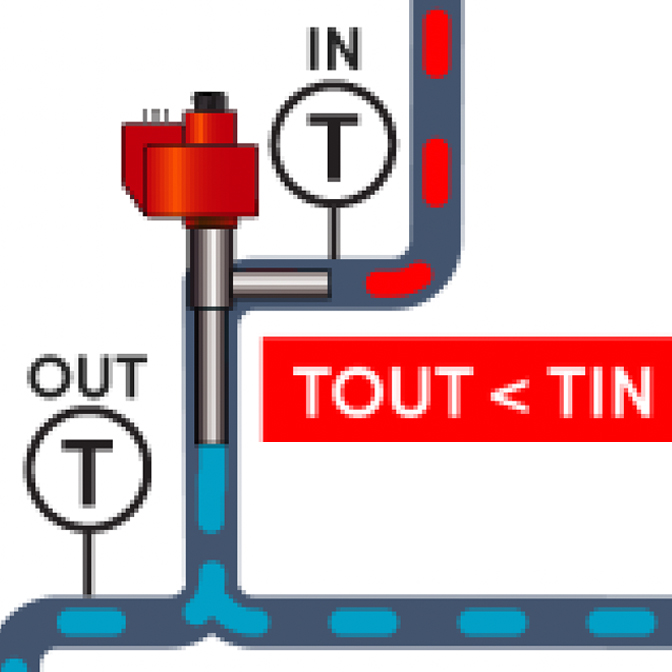

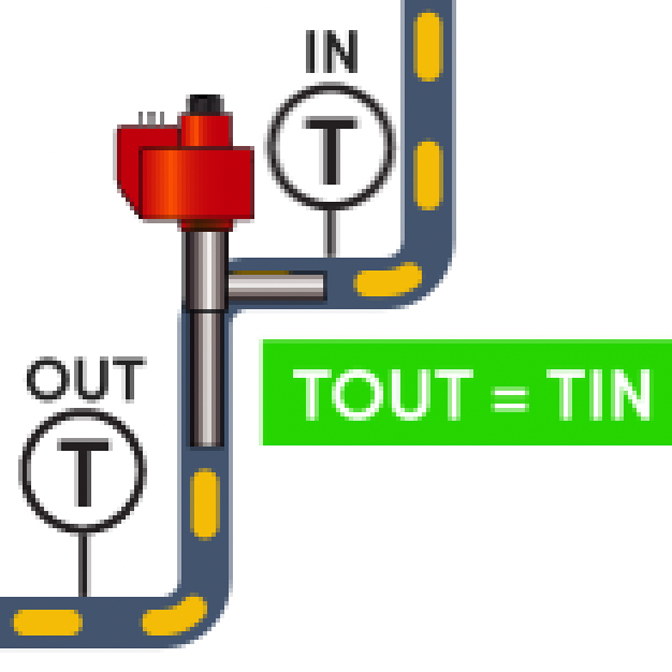

MultiDC Oil Control System

Patented oil control system

|

multiDC features an innovative oil management system, a crucial element for an efficient and reliable system. By periodically opening special electronic expansion valves, the controller checks for oil in the compressor using a dedicated software algorithm:

Furthermore, the same logic can be applied to balance the oil level in all active compressors in the line. If this is not sufficient to supply any compressors with a shortage, oil will be injected from the reserve into the suction line. |

|

||||

|

multiDC features an innovative oil management system, a crucial element for an efficient and reliable system. By periodically opening special electronic expansion valves, the controller checks for oil in the compressor using a dedicated software algorithm:

Furthermore, the same logic can be applied to balance the oil level in all active compressors in the line. If this is not sufficient to supply any compressors with a shortage, oil will be injected from the reserve into the suction line. |

MultiDC System components

MultiDC System components

|

pRack controller

|

|

pR multi DC

|

|

Electronic expansion valves

|

|

R744 DC Inverter Rotary compressor

|

MultiDC - A centralised and integrated system

A centralised and integrated system...

|

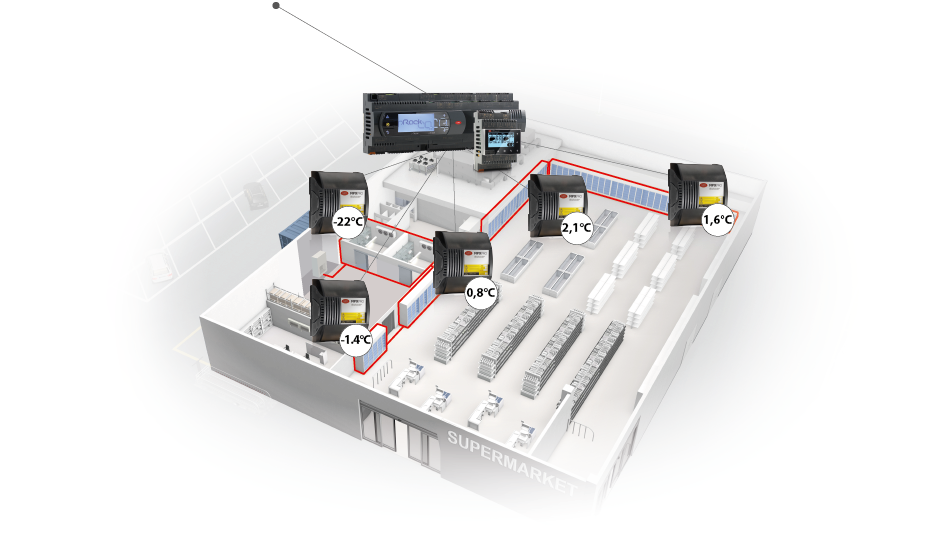

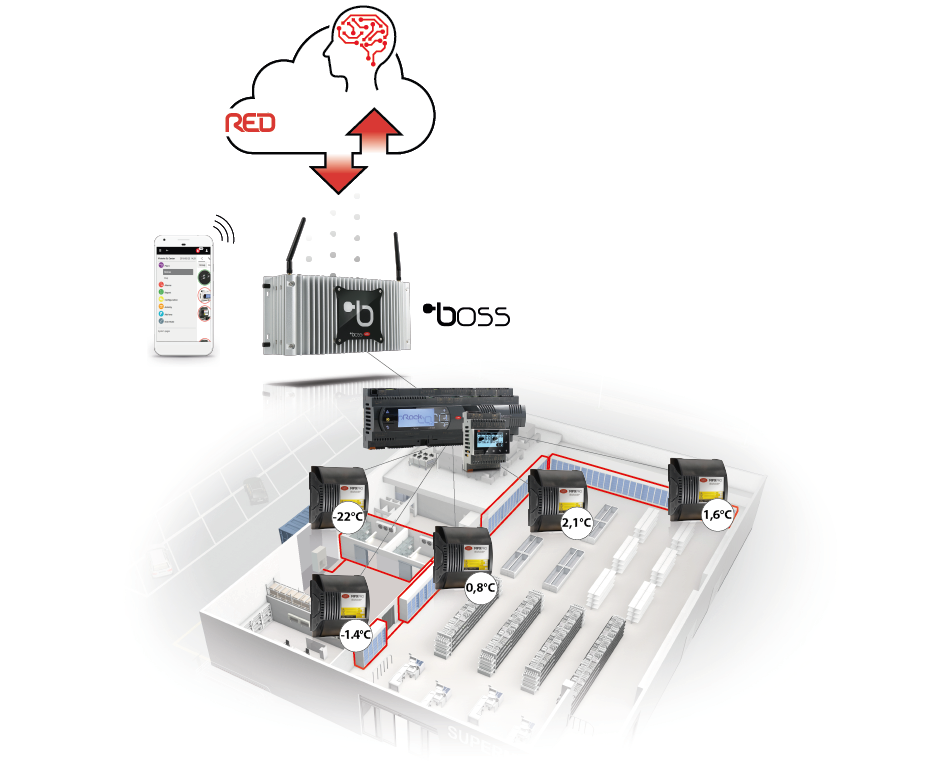

The integrated solution comprising pRack controller, the new pR multi DC and boss supervisor, provides:

|

|

|

|

|

The integrated solution comprising the pRack controller, the new pR network manager and the boss supervisor ensures:

|

MultiDC - Advanced features

…with advanced features

Site management with the latest technologies available in the world, Internet of Things, with dashboard systems for immediate and simple management READ MORE |

|

|

|

|