Humidification technologies

Immersed electrode humidifiers

Immersed electrode humidifiers, by applying a voltage to metal electrodes immersed in common drinking water, heat the water (Joule effect) until boiling, producing steam. The quantity of steam produced is proportional to the electric current, which is in turn proportional to the level of water.

This electric current is measured by a current transformer: by varying the level of water using a fill solenoid valve and drain pump, the current, and consequently the steam production, can be modulated.

Due to evaporation, the level of water decreases and must therefore be topped up. As steam does not carry mineral salts, the salt concentration increases until the water becomes potentially corrosive; the sophisticated control software keeps the water concentration at the optimum value, creating the best compromise between water and energy economy, and humidifier life. Lime scale is deposited over time and covers part of the cylinder, which can easily be replaced or cleaned.

Compared to the complementary immersed element heater or gas humidifiers, immersed electrode humidifiers:

- are less expensive to purchase;

- operate on drinking water (not completely demineralised or softened);

- require the periodical replacement (or cleaning) of the cylinder;

- feature modulation suitable for comfort or industrial applications, without extreme requirements.

Electric heater humidifiers

Immersed heater humidifiers heat the water until boiling, thus transferring heat from the hot element (electric heater) to the liquid. These appliances can operate on demineralised water, as they do not exploit the electrical conductivity of the water, and periodical maintenance can therefore be greatly reduced, due to the minimum formation of lime scale.

Weighing against this, the resistive elements must always be completely immersed in the water, to avoid overheating, and consequently sensors are need to measure the water level. To precisely modulate the steam flow-rate, components (solid state relays) are used to apply power with a variable duty cycle.

These characteristics make the heater units more complex than their counterparts with electrodes, yet independent of the characteristics of the water, and with much more precise modulation of the flow-rate. In addition, as heater humidifiers are intrinsically subject to overheating, the quality of design and the presence of safety systems are essential to ensure reliable service over time.

Immersed heater humidification, complementary to immersed electrode humidification, is becoming increasingly present in work specifications where:

- humidity must be controlled precisely (museums, laboratories, cleanrooms);

- the quality of the water is not constant or is problematic (for example, aboard ships);

- periodical maintenance needs to be minimised (using demineralised water).

Gas-fired steam humidifiers

Gas-fired humidifiers use a local burner/heat exchanger system to produce steam, consequently combining the low-cost operation typical of the combustion process with the simplicity, in installation terms, of a stand-alone appliance.

The installation, maintenance and surveillance problems involving the gas assembly are similar to those encountered with residential boilers for the production of hot water, which use the same devices.

The heat exchanger is generally made from stainless steel or aluminium, and is contained in a tank, it too normally made from stainless steel, filled with water to a constant level. Inside the heat exchanger is the combustion assembly, generally featuring premix burners, metal fibre combustion head and flame sensors.

The flame, and consequently steam production, is modulated continuously by controlling the combustion air fan speed.

Gas-fired humidification, complementary to electrically powered humidification, is generally preferred to the latter when:

- there are high humidification loads (heavy-duty applications)

- the cost of gas is lower than electricity and consequently running costs need to be kept down

- the user is willing to accept a higher initial investment to obtain ongoing savings over time

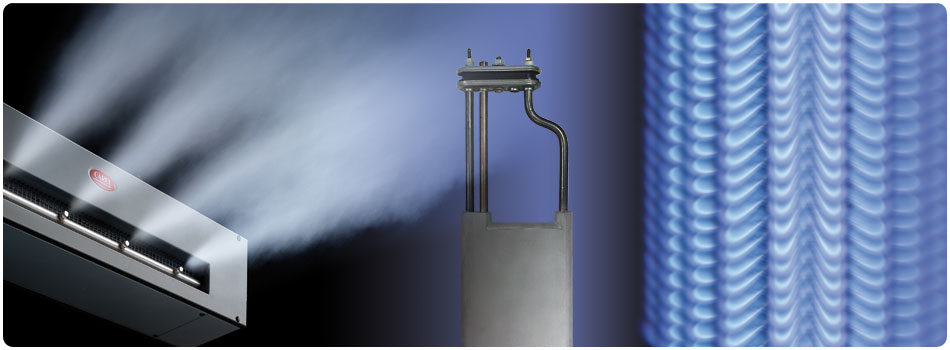

Centralised steam distributors

Direct steam humidifiers are designed to receive pressurised steam from a centralised system and distribute dry steam directly into a duct or air handling unit.

Advantages:

- minimum absorption distance: the outlet of steam through continuous slits (rather than through nozzles, as in most of the competing systems) creates a thin layer of steam that flows uniformly from both sides of the distributor, creating a large surface of contact with the air, allowing a minimum absorption distance (typically half the distance of conventional systems);

- minimum losses due to condensation: the distributors are coated with a layer of very high tech ceramic insulation (deriving from aerospace applications), which reduces by up to 90% the losses due to condensate and the heating of the surrounding air;

- no emission of droplets of condensate: the steam distributors trap and return any droplets of condensate back to the centre of the pipe, where these evaporate again.

Adiabatic humidifiers for AHU/ducts and rooms

Adiabatic humidifiers bring about the direct evaporation of water into the air without adding external energy, and therefore without raising the temperature; the heat required for evaporation is supplied by the humidified air, which consequently is cooled.

These devices create a large interface surface between the air and water in the liquid state, on which a thin layer of saturated vapour forms, with a partial pressure equal to the saturation pressure at the temperature of the liquid.

If this pressure is greater than the partial pressure of the water vapour present in the air, as occurs when the water temperature is higher than the dew point of the air and the air is not saturated, there is a pressure gradient that brings about the progressive evaporation of the liquid at the expense of the sensible heat of the water and the air.

This principle is used by atomising humidifiers, which generate very small droplets whose diameters are in the order of millionths of a metre. These droplets have a huge surface area, meaning the water is rapidly evaporated. Every 1 kg of water split into droplets with a diameter of 10 micrometres has a surface area of 600 square metres!

The main advantages of atomising (adiabatic) humidifiers are:

- very low electricity consumption: high pressure systems need less than 4 Watts per kg/h of capacity, against the 750W of steam humidifiers

- high capacity: the capacity can range from just a few kg/h (for example, humiSonic has a minimum capacity of 0.5 kg/h) to thousands of kg/h (humiFog)

- very low maintenance, in particular when supplied with demineralised water

In the past, adiabatic humidifiers were not used in applications that required very high hygiene, mainly because they recirculated the water. Today, on the other hand, the more advanced adiabatic humidifiers have a high absorption efficiency (ratio between the water absorbed by the air and the amount sprayed) and therefore do not recirculate the water. In addition, stagnation of water is avoided through periodical washing and emptying cycles, the use of demineralised water and bacteriostatic materials. Humifog, for example, has been certified by the Berlin air hygiene institute as being compliant with the strictest hygiene regulations, specifically VDI6022.

Adiabatic humidifiers are increasingly used for energy saving applications: direct or indirect evaporative cooling in air handling units, or alternatively directly into rooms, with very low electricity consumption bringing considerable cooling of the air using simple water.

Centrifugal humidifiers

Centrifugal humidifiers use a spinning disk to atomise the water and transform it into millions of very small droplets that, blown by a built-in fan, are introduced into the environment, where they evaporate, humidifying and cooling the air.

These humidification systems are simple, economical and easy to maintain.

Humidifier operation is controlled by an electronic board inside the humidifier that, as well as managing the normal operation of the appliance, also performs a tank washing cycle when starting the unit, and an emptying cycle at the end of the humidification request. This avoids having stagnated water inside the unit.

Each centrifugal humidifier must be connected to an electrical panel, supplied by CAREL, to manage one or two humidifiers in parallel. They can operate on both mains water and treated water (see the technical specifications).

Ultrasound humidifiers

A piezoelectric transducer, immersed in water, converts the applied electricity into high-frequency mechanical vibrations. The water, due to its mass, is not able to keep up with this mechanical oscillation and thus creates successive waves of compression and depression, during which the cavitated water boils at low temperature and pressure, creating a very fine mist.

Advantages:

- Very low power consumption

- Use of demineralised water: prevents problems due to bacteria and other contaminants.

- Dual effect: humidification, due to the adiabatic effect, ensures simultaneous cooling of the air, with a consequent decrease in refrigerant compressor running time.

- Finely atomised water: particles with a diameter of a few microns are easily and quickly absorbed by the air.

Compressed air and water atomisers

The operating principle of the compressed air and water atomisers involves using compressed air to atomise the water into very fine droplets.

The droplets evaporate spontaneously in the air, humidifying and cooling it. Indeed, evaporation occurs by "absorbing" sensible heat from the air that, as a consequence, is cooled.

The system essentially consists of:

- the control cabinet, fitted with electronic controller;

- special atomising nozzles that can be installed in an AHU/duct or directly in the room being humidified/cooled;

- manifolds for installation in the duct;

- UV lamp sanitation system and protection filters.