Textile industry

-

General characteristics

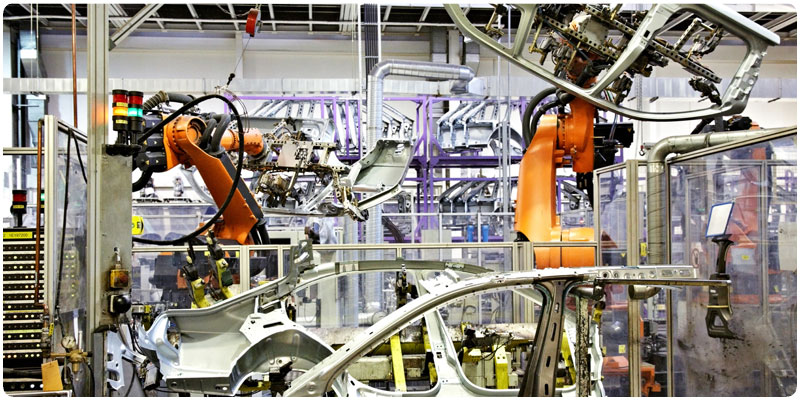

In the textile industry, keeping the relative humidity of the air within preset limits improves the efficiency of the process and ensures the best quality of the finished product. In fact, the air humidity level affects the properties of the yarn and its workability

When the air is too dry, the fibers lose their elasticity, are thinner, fragile and tend to break; friction also increases, which limits the sliding of the fibers on the machine. This can cause machine downtime, require manual interventions and therefore result in a productivity reduction.

Keeping humidity within preset levels also helps reduce the amount of dust in the air. This improves the quality of the environment where the products are processed or stored, eliminating the risk of small dust puffs clogging the moving structures.

A proper level of humidity eliminates the risk of static electricity build-up, which makes the processing of the material more difficult and which may even cause damage to the equipment.

An equally important fact is that excessively dry air favors the shrinkage of the fabric. Maintaining humidity constant allows for achieving greater reliability in cutting and for complying with the size specifications, which is critical for example in the carpets' manufacturing.

In some cases the textile machinery develops a lot of heat, which causes an undesired ambient temperature rise. In this regard, the adiabatic systems are the optimal technology, as they allow for the simultaneous cooling and humidification of the air.

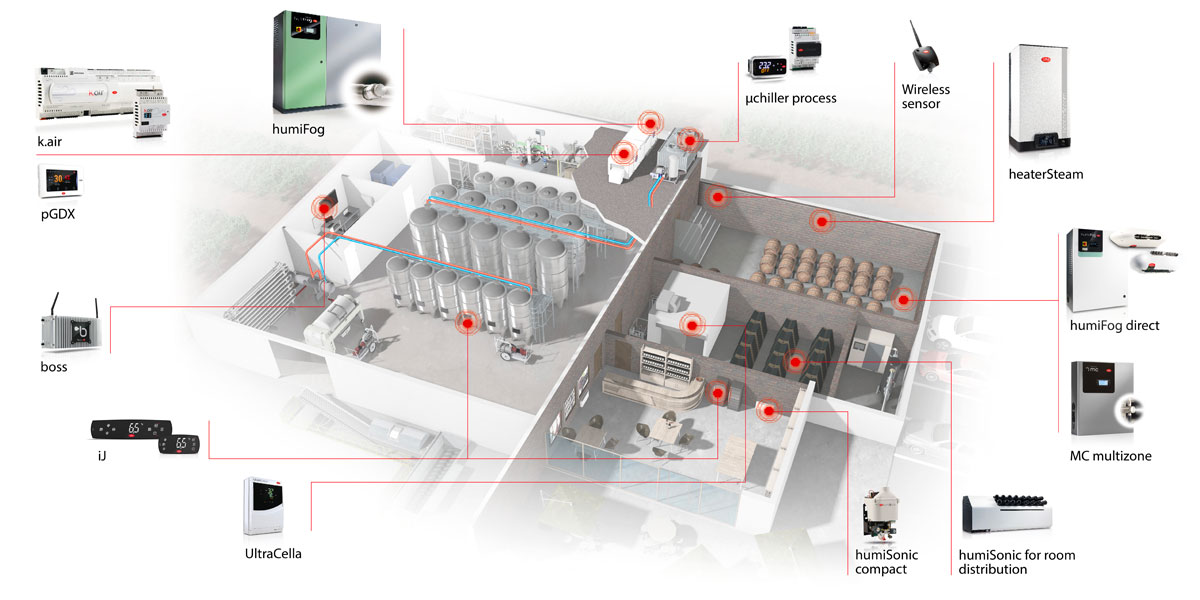

Carel offers a wide variety of steam and adiabatic humidifiers, in a wide range of capacities and characteristics. The adiabatic humidifiers, in particular, operate by atomizing water in millions of tiny droplets that evaporate spontaneously, absorbing the heat from the air. They are reliable and energy saving systems; the most efficient ones hardly consume 4W per litre of atomized water. -

Plus

Humidify the air in order to: - Making the fibres less fragile,while improving their workability, thus maximizing the efficiency of the process;

- Reduce the amount of dust in the air;

- Prevent the build-up of static electricity;

- Cool the air, absorbing the heat generated by the machines.

Documentation

Commercial

-

Other related documentation

* Entries are ordered by date

Code Description Language Date * Release +3000193EN Direct humidification: Advanced solutions for industrial and commercial environments ENG 29/05/2025 1.2 +3000193IT Umidificazione diretta: Soluzioni all’avanguardia per ambienti industriali e commerciali ITA 29/05/2025 1.2