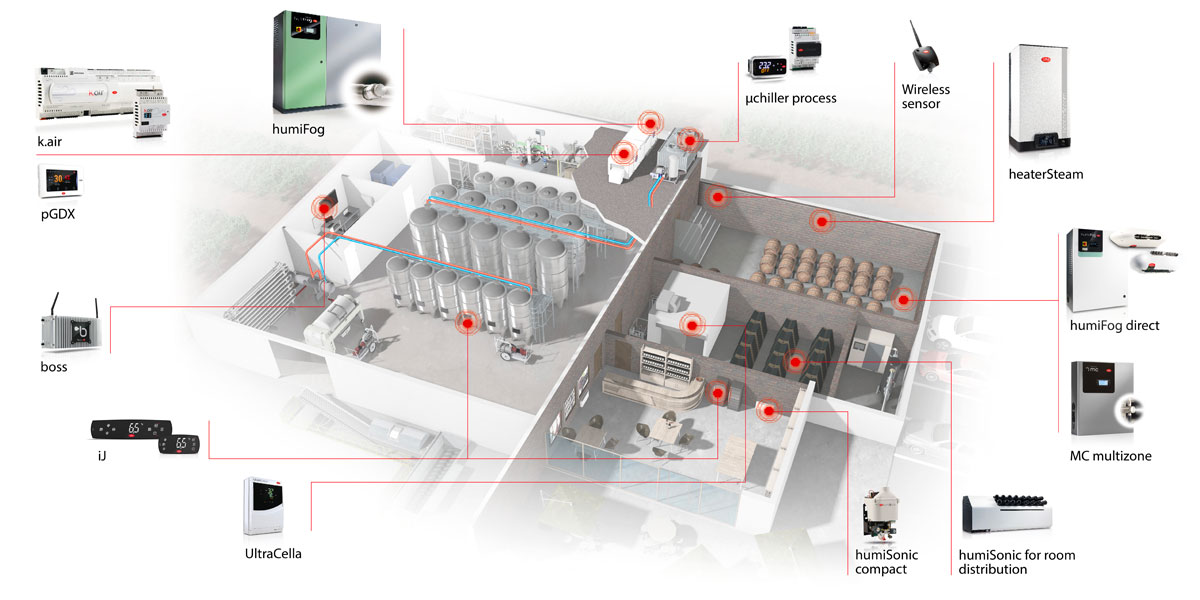

In an air-conditioning system, the heat taken away by chillers and drycoolers decreases as the outside temperature increases: in summer, evaporative cooling can often be exploited to improve system operating conditions.

Most chiller and drycooler installations are in fact sized based on the maximum outside temperature: the influence of this factor has grown in recent years, in response to intense summer heat waves. Oversizing of appliances means more pollution, higher noise levels and extra investments in terms of heat exchange surface area, which is not used during periods when demand is lower.

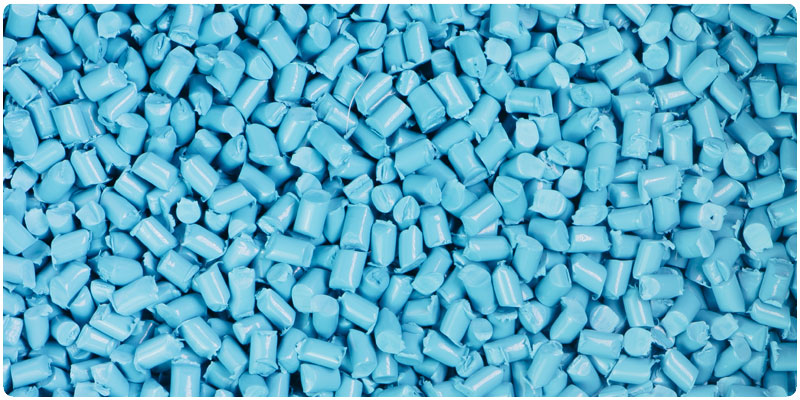

Evaporative coolers boost system operation in these specific conditions. Carel offers pumping and distribution systems that spray finely atomised water into the air stream that flows through the coils. These droplets of water evaporate spontaneously, absorbing energy from the air that is consequently cooled, and comes into contact with the finned coil at a lower temperature. In this way, the heat exchanger can dissipate the rated amount of heat even when the climate is hotter than expected. Moreover, the atomised water particles do not evaporate completely before reaching the finned coil, and consequently the heat exchanger fins are wetted, further increasing overall system efficiency. Atomisers used for evaporative cooling applications can operate on untreated mains water or demineralised water, and are very simple to manage: all that is needed is a pressure switch in the refrigerant circuit.

In a typical system designed to work at an outside temperature of 26°C and a relative humidity of 50%, when using evaporative cooling, at 30°C a drycooler has an equivalent capacity to operation at 25°C without evaporative cooling. Assuming then that variable speed fans are available, controlled by inverter, the system can reach even higher levels of efficiency, even at low temperatures.

Compared to evaporative cooling systems that do not use atomised water, for example wetted media, this system has several benefits: easy installation, even in retrofit applications, more precise control with less water consumption, lower maintenance costs and no pressure drop in the ventilation system.