Solutions for condensing units

Complete range of CO2

CONDENSING UNIT solutions

In the retail refrigeration sector, highly innovative solutions are increasingly in demand, guaranteeing high energy efficiency and a low environmental impact.

The recent introduction of a complete range of CO2 condensing unit solutions can now completely satisfy current market requirements.

In the retail refrigeration sector, highly innovative solutions are increasingly in demand, guaranteeing high energy efficiency and a low environmental impact.

The recent introduction of a complete range of CO2 condensing unit solutions can now completely satisfy current market requirements.

- Natural refrigerants (CO2)

- Reduced energy consumption

- Compliance with F-gas and Ecodesign regulations

- Control stability and excellent food preservation

- Easy installation and commissioning

- Total connectivity

Hecu CO2

|

Hecu CO2Hecu sistema is CAREL’s high efficiency solution for transcritical CO2 condensing units. Specifically designed to serve small and medium-sized stores, it achieves new levels of energy efficiency and control stability through DC inverter technology.

conventional technology |

Hecu CO2Hecu sistema is CAREL’s high efficiency solution for transcritical CO2 condensing units. Specifically designed to serve small and medium-sized stores, it achieves new levels of energy efficiency and control stability through DC inverter technology. |

||||||||

|

||||||||

conventional technology |

Hecu CO2 in detail

MT Solution

Up to 8.3 kW (Transcritical operating conditions, Evap.T -10°C) |

LT Solution

Up to 7.0 kW (Transcritical operating conditions, Evap.T -35°C) |

MT Solution

Up to 8.3 kW (Transcritical operating conditions, Evap.T -10°C) |

|

LT Solution

Up to 7.0 kW (Transcritical operating conditions, Evap.T -35°C) |

Hecu CO2 components

Hecu components

|

Hecu controller

|

||

|

pLD PRO user interface

|

||

|

|

||

|

|

||

|

R290 DC Inverter Rotary compressor

|

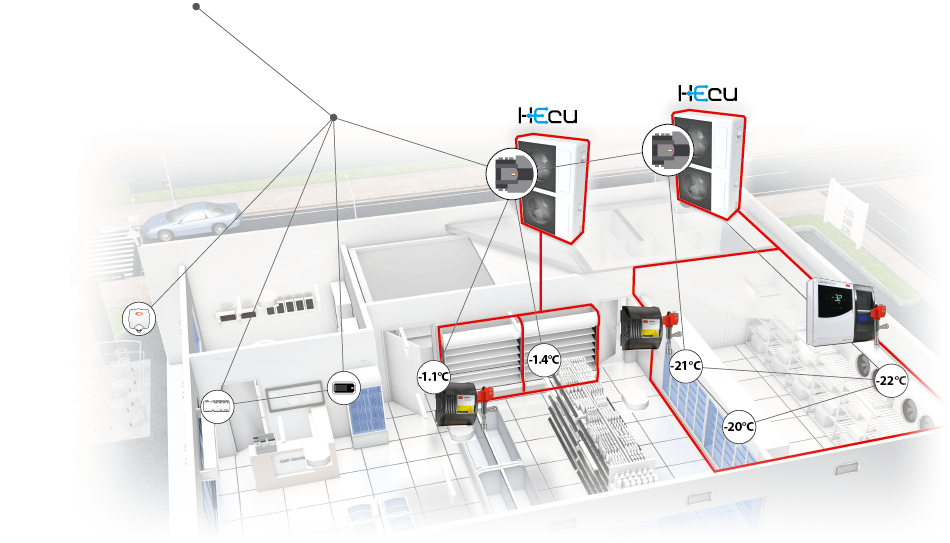

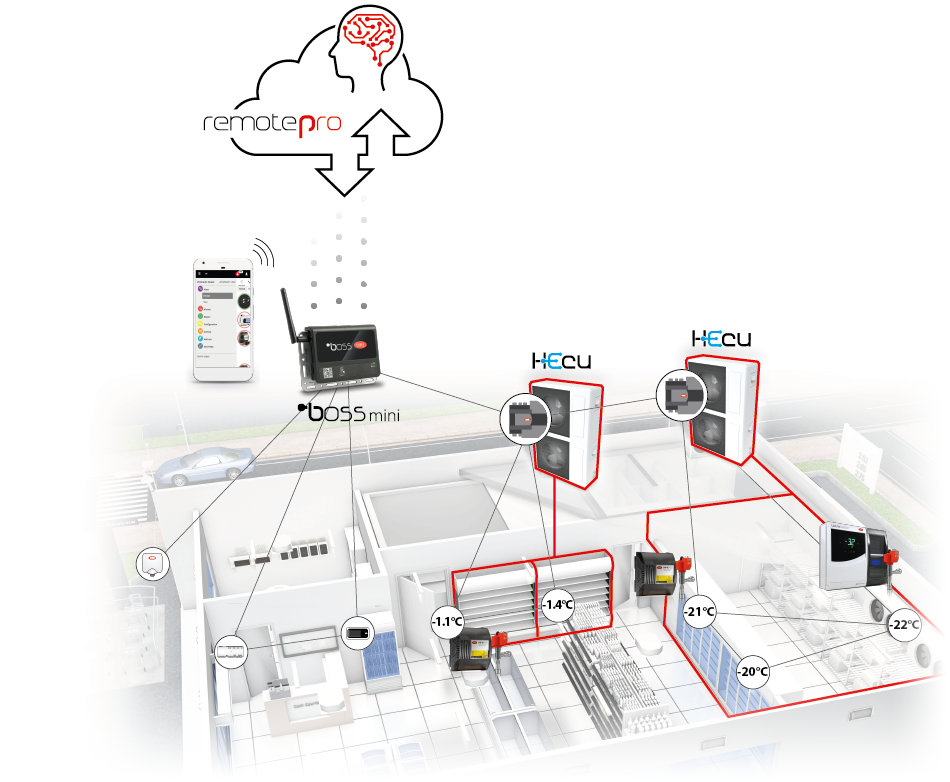

Hecu CO2 connectivity

Advanced connectivity

|

Synchronisation with refrigeration units

Always connected

|

|

|

|

|

Synchronisation with refrigeration units

Always connected

|

Standard technology solution for CO2 condensing units

Conventional technology solution for CO2 condensing units

|

|

||||||||||

|

|

|

|

|

|

User simplicity |

Energy saving |

System optimisation |

ECO-Friendly |